The AQUIKO product range has been designed and manufactured in the UK using the most cutting-edge techniques. Our products are made from HDPE & stainless steel 316, adhere to BS7775 and have a design life of 50 years.

The HDPE used in our products is black. The black HDPE is stabilised against UV light, this is achieved through the addition of 3-5% carbon. This process increases the material’s resistance to both high impact and corrosion (in both temperature extremes). Black HDPE is widely used in commercial and industrial industries such as the mining, agriculture, marine and food industries.

The added carbon prevents ultraviolet rays from passing through which can damage the polyethylene molecular chain. Because the HDPE is black, the material is stabilised against ultraviolet light, meaning it does not degrade or powder in sunlight as PVC does for example. This ensures there are little or no microplastics.

There is also no abrasive friction on the HDPE in our products like there is on a car tyre, for example, so virtually no microplastics will be created from abrasion. The seal is water lubricated and slides smoothly over the surface – once again minimising the risk of microplastics again. Polymer sealing systems are required for any fabricated flow control regardless of the main manufacturing material.

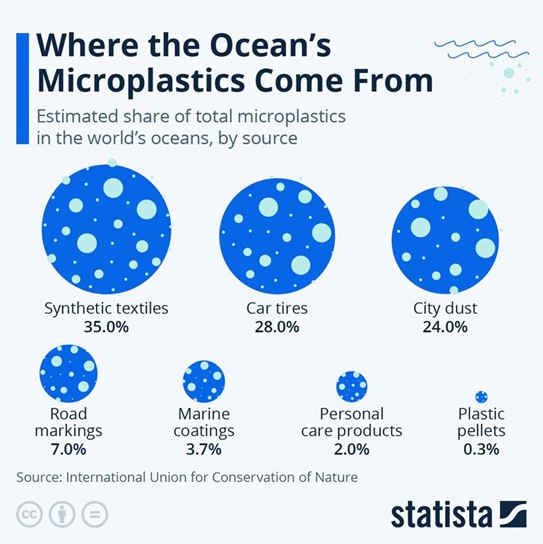

As you will see from the below most microplastics come from synthetic textiles, car tyres and city dust which is mostly made up of PVC UV degradation from drainpipes, windows etc. It is also good to consider that 3.7% of the oceans microplastic comes from marine coatings, which are the very same coatings that are applied to cast iron and steel alternatives.