AQUIKO Flush Invert Penstocks can be built to match our customers specification. Please fill in the form with your requirements and we will get back to you.

Description

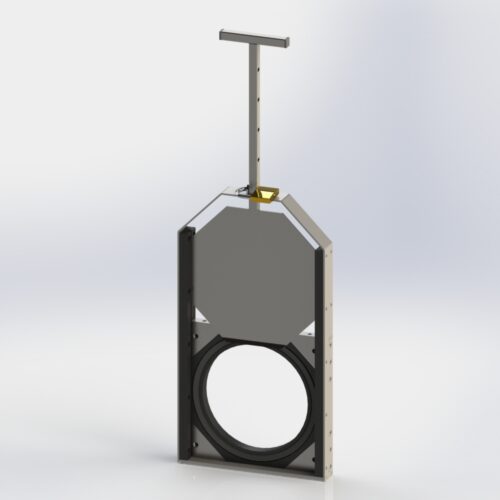

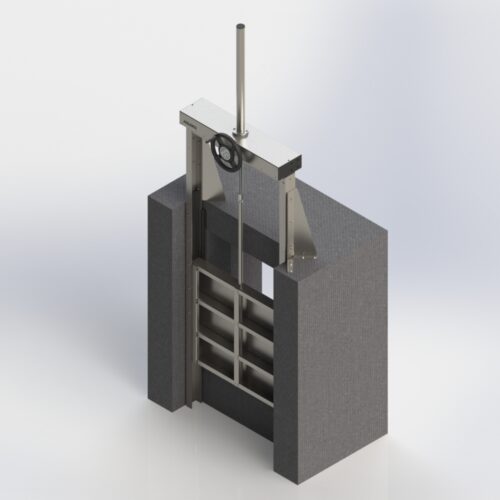

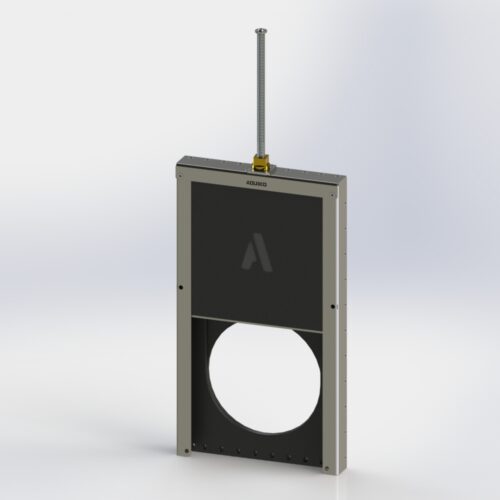

Flush Invert Penstock – AQUIKO Floor-Level Water Control Gate

The AQUIKO Flush Invert Penstock is specifically designed for installations where the invert of the channel or pipe is required to be flush with the finished floor or chamber level, eliminating moulded recesses, simplifying civil works and removing potential debris traps. According to our specification, the unit features a bottom sealing face in stainless steel anchored directly into the concrete invert — no casting of a sill required.

Key Features & Benefits

-

Flush installation: The bottom sealing face of the unit is a stainless-steel strip which can be anchored into the concrete invert, enabling a completely flush floor surface and avoiding the need for additional recess or formwork.

-

Reduced debris traps: Because the invert is flush and no recess is needed, debris cannot accumulate in a sill—improving reliability.

-

Simplified civil works: No extra casting, no additional formwork required — enabling faster installation and reduced cost.

-

Robust design: Suitable for demanding flow-control or flood-defence applications where a clean invert interface and reliable seal are critical.

-

Partner-friendly for contractors & resellers: Standard sizes available, UK-manufactured, stocked ancillary kits for rapid deployment.

Technical Specification Snapshot

-

Model: Flush Invert Penstock (floor-flush invert)

-

Bottom sealing face: Stainless-steel strip anchored into concrete invert.

-

Material options: HDPE door with stainless-steel frame/reinforcement (or all stainless versions on request) — typical for heavy duty flush invert models.

-

Head pressure & duty: Standard flush invert units are available for moderate to high head applications (e.g., up to 5 m w.c. in some cases).

-

Installation: Frame anchored into concrete; the invert is flush with the channel/pipe floor. Ensure wall/channel surface is flat and smooth to preserve seal performance.

-

Maintenance: Designed for minimal maintenance thanks to smooth invert and no bottom sill; inspection intervals recommended as per site conditions.

Typical Applications

The Flush Invert Penstock is especially well suited for:

-

Drainage outfalls or chamber installations where the floor must remain level or flush with the invert of the pipe

-

Civil infrastructure where minimal interruption and clean floor interface are required (e.g., city drainage chambers, control shafts)

-

Flood defence installations requiring high reliability and little debris build-up beneath the gate

-

Contractor stock for quick turnaround installations and resellers offering differentiated specification options

Why Choose AQUIKO Flush Invert Penstocks

When you work with AQUIKO you benefit from:

-

UK manufacture — predictable lead times, UK stock support, easier logistics for contractors and resellers

-

High-spec materials — HDPE and stainless options tailored for long service life in harsh installation conditions

-

Installation time-saving features — flush invert design means less civil work, less formwork, faster deployment

-

Technical support & partner service — drawings, data sheets, accessory kits, installation advice and responsive support for resellers and contractors

Ordering & Availability

Standard sizes are held in stock or ready to manufacture to deliver rapid supply across the UK market. Bespoke sizes (for larger apertures, non-standard mounting, or extreme head pressures) are available on request.

To place an order or request a quote, please provide:

-

Aperture width and height (or bore/invert dimensions)

-

Head pressure or operating conditions

-

Materials requirement (HDPE vs stainless)

-

Mounting details: flush invert required, chamber / channel environment

-

Accessory requirement: hand-wheel, actuator, locking kit

Fixing kits, gaskets, guide rails and ancillaries can all be supplied to complete your installation package and support your contractor deliverables.

Related Products You May Be Interested In

-

Standard Penstocks – for installations where a traditional sill is acceptable or head conditions vary

-

Inline Penstocks – for pipeline or culvert in-line installations

-

Hand Stop Gates – compact isolation gates for smaller apertures

Talk to Our Team ????️

Have a project that needs a smooth-floor, high-reliability isolation gate? Whether you’re a contractor needing rapid stock delivery, or a reseller looking to offer next-level specification, our team is ready to help.

Call 01777 819 734